DIGITAL VARIABLE AREA FLOW Controller: MASS-VIEW®

THE INTELLIGENT MASS FLOW Controller

The MASS-VIEW® series operate on the principle of direct thermal mass flow measurement. A major advantage of using this type of sensor is that the instruments measure direct mass flow, without the need for temperature and pressure correction.

The MASS-VIEW® has compared to conventional VA meters high accuracy and rangeability (up to 1:100). The 10 pre-installed gases eliminate the need to recalibrate for different gases and therefore reduce the cost of ownership. For your convenience, we also have our flow ranges in other flow units.

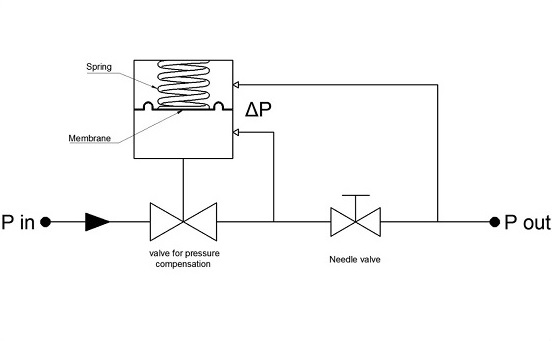

Flow control is achieved by keeping the pressure drop across the needle valve constant. With a varying upstream pressure, the flow will nearly be constant.

Read below for the operation of the manual controller in combination with the built-in membrane.

Only need to measure the flow? MASS-VIEW Meters Want to regulate the flow? MASS-VIEW Regulators

Pre-installed Gases | MV-401 | MV-402 |

| Air, N2, O2, CO2, CO and N2O | 20 .. 200 mln/min (CO2 and N2O n.a.) | 20 .. 2000 mln/min |

| Ar | not available | 40 .. 4000 mln/min |

| CH4, C3H8 and C4H10 | not available | 10 .. 1000 mln/min |

Achieve a stable flow using a valve

Achieve a stable flow using a valve

A VA meter, whether it is a conventional or a digital one, can be equipped with a built-in needle valve. This needle valve enables the user to regulate the flow rate by means of a restriction inside the flow channel. As long as the inlet pressure is stable, the subsequent flow will be stable too.

On the other hand, once pressure conditions are susceptible to change, the flow rate will become equally unstable. If this is not desirable, you’ll have to compensate these pressure fluctuations.

This effect can be eliminated by using a manual control valve like the MASS-VIEW Controller-series which keeps the pressure drop across the needle valve (delta-P) constant.

This is accomplished by a second (normally open) valve, though it is operated by a membrane this time. The operating principle is based on a balance that forms between the pre-pressure, back-pressure and the spring force on the mebrane. A change in the pressure conditions leads to a change of the equilibrium and thus a change in the valve position as well (as shown in the picture below).

in the valve position as well (as shown in the picture below).

Although Bronkhorsts’ pressure compensation technology is suitable for either gases and liquids, the nice thing about this is that both technologies, the digital VA meters and pressure compensation, lend themselves well to being built together. However, in that case it is applicable for gases only.

Example:

The inlet pressure is 3 bar (a) and the flow is set (by turning the knob) to 40% (for the MV-401, this is 80 mln/min).

If you then increase the inlet pressure to 8 bar (a), the flow may deviate by a maximum of +/- 1.5%, which means it will be between 81.2 mln/min and 78.8 mln/min.