MASS-VIEW series applied to the nuclear industry

The French based company Premium Analyse is specialized in the detection of radioactive gases. They are successfully active in the nuclear industry and they are able to deliver turnkey solutions on requests. Their radiation measuring devices are suitable for applications in process control, radioprotection, environmental protection, dismantling and research. Discover in this article in which way the MASS-VIEW® series adds value to their business.

“We have chosen the MASS-VIEW® with a great pleasure“

Application set up

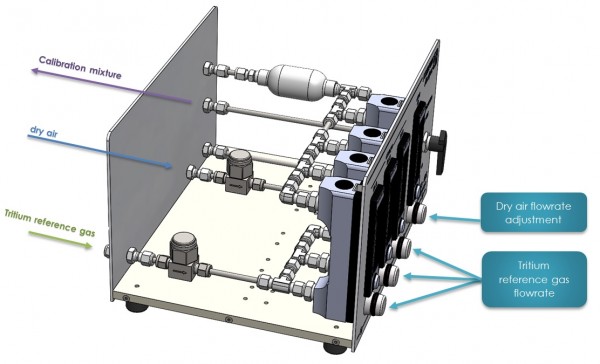

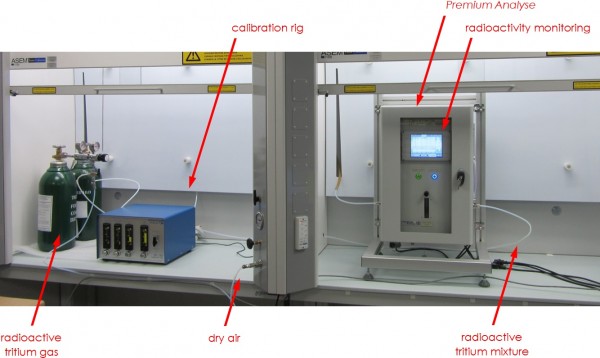

The BE-3M is a calibration rig designed and constructed by Premium

Analyse. On the backside it connects to a bottle of standard radioactive tritium reference gas with a known volume activity. Additionally it connects to a source of compressed, filtered, dry and oil free air. Through the integrated MASS-VIEW’s (MV-301, MV-302 and MV-304) it allows then to dilute the reference gas with the air in proportions ranging from 1 to 10.000 in order to obtain a mixture flow of determined activity. In this way the set up periodically measures response and linearity of radioactive tritium gas at three fixed points along their measuring range.

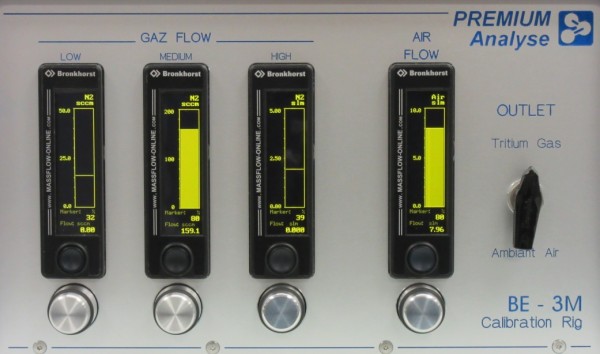

Each mass flow meter is configured to allow a low, medium or high dilution of the tritium reference, in order to obtain a mixture of high, medium or low activity.

For instance, in figure 4 the “Gas Flow – Medium” shows a flow set at ~160 sccm of a tritium gas with an activity of 200 MBq.m3. The “Air Flow” MASS-VIEW® has a flow set at ~8 slm of dry air. So, the rig gives a mixture of 200 ∙ 0.159/(0.159 + 7.96) ~ 3.92 MBq.m^3.

Added value of the MASS-VIEW®

For multiple criteria the MASS-VIEW® shows its added value to the calibration rig. The criteria are listed below:

- The compactness of the MASS-VIEW® allows to construct a portable and easy-to-use rig.

- The selectable flow ranges allow to use the flowmeters in different mix configurations.

- The needle valve and the digital display remind the end-user to the conventional VA meters. Therefore the end-user is more comfortable with the design than with a whole computer controlled apparatus.

- The use of the flow marker allows to indicate the end-user the best configuration of the different flows for an ideal operation of the rig.

- Cost-effective; this is important in the radioactivity field, in which the control devices are frequently maintained or changed.