What is the difference between mass flow meters and volume flow meters?

The ranges of thermal mass flow meters for gases are specified in such units as ln/min, sccm or m3n/h.

These units look like volumetric units, but in truth they are expressions of Mass Flow. What is the story behind this?

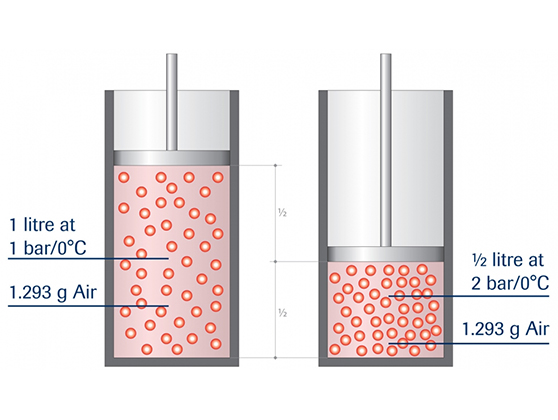

Imagine you have a cylinder of 1 litre, which is closed by means of a moveable piston of negligible weight.

This cylinder contains 1 litre of air at ambient pressure, approx. 1 bar.

The weight of this volume of air at 0°C is 1.293 g, this is the mass. When we move the piston half way to the bottom of the cylinder, then the contained volume of air is only ½ litre, the pressure is approx. 2 bar, but the mass is unchanged, 1.293 g; nothing has been added, or left out.

Following this example, mass flow should actually be expressed in units of weight such as g/h, mg/s, etc.

Most users, however, think and work in units of volume. No problem, provided conditions are agreed upon, under which the mass is converted to volume.

Following the ‘European’ definition, a temperature of 0°C and a pressure of 1,013 bar are selected as “normal” reference conditions, indicated by the underlying letter “n” in the unit of volume used (mln/min, m3n/h).

Alternative, a temperature of 20°C and a pressure of 1,013 bar are used to refer to “standard” reference conditions, indicated by the underlying letter “s” in the unit of volume used (mls/min, m3s/h).

Please be aware of this, because if the difference is not considered, it may lead to an error of 7%!

According to the ‘American’ definition the prefix “s” in sccm, slm or scfh refers to “standard” conditions 101.325 kPa absolute (14.6959 psia) and temperature of 0°C (32°F).

Volumetric measuring devices, like variable area meters or turbine flow meters, are unable to distinguish temperature or pressure changes. Mass flow measurement would require additional sensors for these parameters and a flow computer to compensate for the variations in these process conditions. Thermal mass flow meters are virtually insensitive to variations in temperature or pressure.