What is the sensor principle of MASS-VIEW?

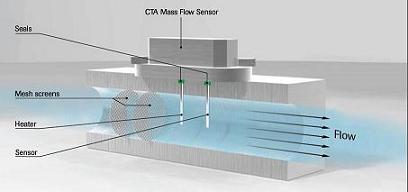

The MASS-VIEW® operates on the principle of direct thermal mass flow measurement. The through-flow design sensor consists of a heater resistor and a temperature sensing resistor and is made of stainless steel. Both resistors are made of temperature sensitive resistive material that is covered with a stainless steel tube. The necessary heating power to keep the temperature difference between the heater resistor and the sensing resistor at a constant level depends on the mass flow. A different and unique heater current is produced for each value of the flow. The measurement principle described is called Constant Temperature Anemometry (CTA).

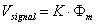

The transfer function between mass flow and output signal can be described by the equation:

Vsignal = output signal

K = constant factor

(includes λ – heat conductivity, Cp – specific heat, μ – dynamic viscosity and ρ – density of the gas)

Φm = mass flow

The working principle is based on King’s law of the ratio between the mass flow and the heater energy. That means the higher the flow, the more energy is required to maintain the chosen ΔT.

The pressure drop over the instrument’s measurement chamber is almost comparable to a straight run of pipe of the same diameter and is thus almost negligible.

Our instruments are suitable for use in the chemical and pharmaceutical industries in mechanical engineering, as well as in gas production.

Based on this concept, mass flow can be measured with low pressure drop, mainly caused by the gas fittings. Compared to traditional thermal MFMs and MFCs with by-pass, the direct measuring MASS-VIEW® is less sensitive to humidity and contamination.

Industries / Applications

- Analytical instruments

- Biogas applications

- Burner controls

- Coating plants

- Exhaust gas measurement

- Gas consumption measurement

- Gas monitoring systems

- N2/O2-generators

- Paint-spray lines

- and more